This is a comprehensive research report on the use of hydraulic flushing technology in coal mining. The main findings can be summarized as follows:

- Impact characteristics of stress waves: The report analyzes the impact characteristics of stress waves generated during hydraulic flushing using statistical methods. It shows that as the strength of the sample decreases, the impact vibration amplitude increases and the stress wave attenuation rate decreases.

- Effect on coal body transformation: The research demonstrates that the stress wave disturbance has a three-dimensional effect on any position inside the coal body, leading to continuous changes in the microstructure and stress state of the coal.

- Three-dimensional vibration mode: The report provides evidence for a three-dimensional vibration mode in the internal structure of coal, showing that the phenomenon occurs regardless of the impact point's location on the surface of the borehole.

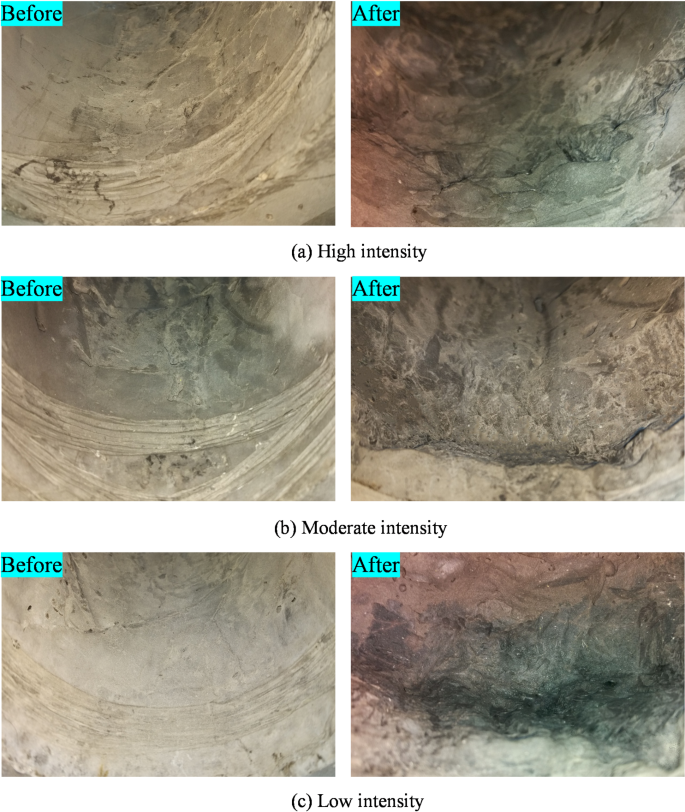

- Impact degree of samples with different strengths: The results indicate that higher hydraulic flushing pressures lead to more extensive damage to the sample surface and stronger expansion of pore sizes.

- Advantages of hydraulic flushing technology:

- Improves extraction efficiency by enhancing gas release and migration within coal structures.

- Reduces gas pressure and outbreak risks, improving coal mining safety.

- Mechanisms underlying changes in coal structure: The report attributes the impact on coal structure to three mechanisms: (i) removing debris generated during drilling; (ii) stretching the surface of coal body by water flow; and (iii) peeling off the coal body.

Overall, the study confirms that hydraulic flushing technology is an effective technique for maximizing coal extraction while ensuring safe mining practices.