China's Dominance in Global Solar Silicon Production

By Ignacio Mártil, Professor of Electronics at Complutense University of Madrid

Madrid, Date - The solar photovoltaic industry, pivotal in the global push towards renewable energy, relies heavily on the production of high-purity silicon, a material integral to manufacturing efficient solar panels. Here's how this critical component is produced and why China has become the world leader in this sector.

The Science of Silicon Production

The journey of silicon in solar technology begins with quartz-rich sand, which is primarily silicon dioxide (SiO2). This sand is heated to an extreme 1,900°C in electric arc furnaces mixed with carbon, typically in the form of coke, to produce molten silicon through a reaction where oxygen from the sand combines with carbon to form carbon dioxide:

[ \text{SiO}_2 + \text{C} \rightarrow \text{Si} + \text{CO}_2 ]

The resulting silicon, known as "polysilicon," is then cooled, ground, and further refined through reactions with hydrochloric acid to produce trichlorosilane, which undergoes multiple distillations to achieve a purity level of 99.99999999%, or "electronic purity."

Geopolitical Dynamics and China's Ascendancy

Initially, electronic-grade silicon was predominantly used by the semiconductor industry, with solar cell production relying on surplus. However, as demand for solar energy surged, particularly with government subsidies in the mid-2000s, the need for photovoltaic-grade silicon exceeded that of the chip industry. This shift prompted significant investments in silicon processing and purification, especially in Asia.

China has emerged as the global leader, with its companies producing approximately 93% of the world's solar silicon by 2023. Companies like GCL-Poly and Tongwei have not only met but exceeded global demand, with plans for further expansion. Tongwei, for instance, is investing $4 billion in a new facility aiming to produce 400,000 tons annually, part of China's broader strategy to support its industrial ambitions.

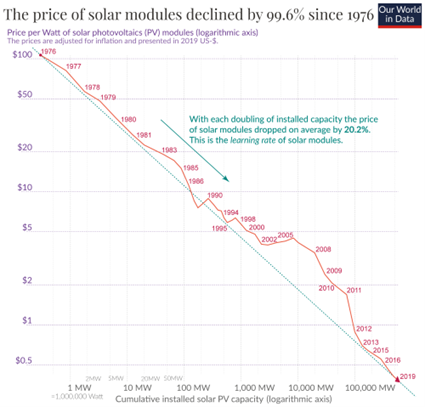

Economic Impacts: The Plummeting Cost of Solar Panels

The solar industry's growth has followed an impressive learning curve, where the cost of solar panels has decreased dramatically. Over the past five decades, as the cumulative installed capacity of solar energy has grown exponentially, the price per watt has plummeted from about €100/W in the 1970s to €0.2/W in 2020, showcasing a 21% cost reduction for every doubling in installed capacity. This decline in cost has not only made solar energy more accessible but has also fostered a competitive environment, pushing manufacturers to innovate in efficiency and cost reduction.

Conclusion

China's strategic focus on silicon production has cemented its role as a dominant force in the solar energy sector, leveraging its manufacturing capabilities to supply the world with solar technology at increasingly competitive prices. This has not only shaped global energy markets but also highlighted the modularity and broad appeal of solar energy, making it a technology that serves both individual consumers and large-scale energy projects alike.

Ignacio Mártil is a Professor of Electronics at Complutense University of Madrid and a member of the Royal Spanish Society of Physics. His insights into the solar industry reflect his deep involvement in energy technology and policy.